Designing

To respect client privacy, we do not showcase their designs. We collaborate closely with clients to develop custom patterns, which are then transformed into design files for upload. With 8 digital dye sublimation printers and a commitment to meeting strict deadlines, we ensure efficient and high-quality results.

Sampling

Clothing development starts with sampling, the most crucial step. Customers provide a clear tech sheet with measurements and details or a sample to replicate with modifications. Our team also assists with material sourcing to ensure the best fit for your needs.

Sampling is essential—it helps resolve any issues before production begins. Once the sample is approved in the correct material, we’re ready for production. For digital printing, our graphics team converts your designs into vector or high-resolution TIFF files, ensuring top-quality results.

Digital Printing

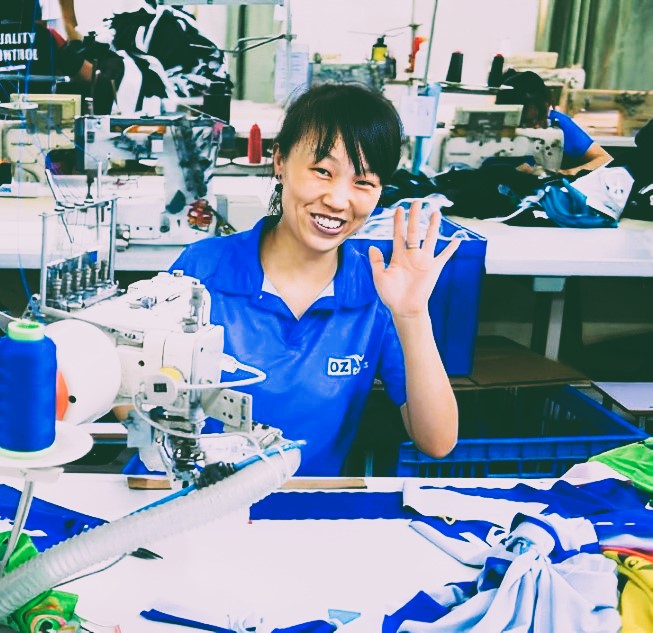

Once your samples are approved, we proceed with custom manufacturing for your clothing label. Our digital sewing machines ensure precise stitching and speed without compromising quality. Strict quality checks before and after ironing guarantee the highest standards.

We manage everything from cutting and sewing to packaging with care. With 8 dye sublimation printers for sportswear and 4 direct-to-garment printers for cotton, we provide expert in-house printing and eCommerce 4PL solutions. Quality is our priority at every step.